-

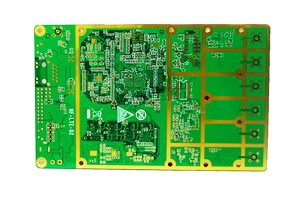

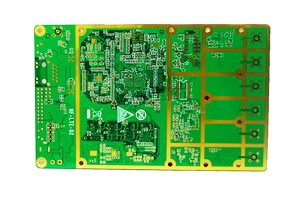

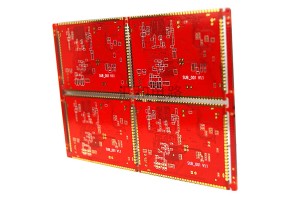

China Wholesale Circuit Board Assembly Manufacturers - 4 Layer ENIG Impedance Control PCB 9115 – Huihe

About the impedance control In the case of transmission of high frequency signals, the controlled impedance helps to ensure that the signal does not decay significantly during transmission. In essence, controlled impedance refers to the matching of the material properties of the substrate to the characteristics of the line/dielectric layer to ensure that the impedance value of the line signal is within the tolerance of the reference value. Controlled impedance PCBs provide reliable and c... -

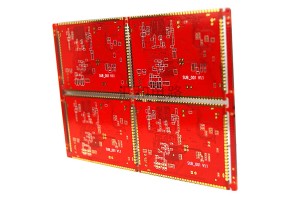

China Wholesale Embedded Pcb Factories - 8 Layer ENIG Impedance Control PCB – Huihe

Impedance is the combination of capacitance and inductance to hinder the circuit under high frequency signal. Impedance is an AC characteristic, which means it is frequency dependent. In the case of transmitting high-frequency signals, the controlled impedance helps to ensure that there is no significant attenuation of the signal during transmission. In essence, the controlled impedance means that the material characteristics of the substrate match the characteristics of the line / dielectric... -

China Wholesale High Speed Pcb Pricelist - 6 layer High TG ENIG PCB 10845 – Huihe

Difference between general FR4 and high Tg FR4 The difference between general FR-4 and high FR4-TG lies in the difference of mechanical strength, adhesion, water absorption, dimensional stability, thermal decomposition of hot state (especially after water absorption) under hot state under different conditions (such as thermal expansion). Obviously, high Tg PCB is better than ordinary PCB substrate material. Therefore, in recent years, there is a great demand for high Tg PCB, but the pric... -

China Wholesale Round Pcb Board Quotes - 12 Layer ENIG PCB 14799 – Huihe

HDI PCB material HDI PCB materials are RCC, LDPE, FR4 RCC:Resin coated Copper is short for resin coated copper foil. RCC is composed of copper foil and resin with rough surface, heat resistance and anti-oxidation treatment (used when the thickness is more than 4mil) The resin layer of RCC has the same processability as FR4 adhesive sheet (prepreg). In addition, it should also meet the relevant performance requirements of the laminate, such as: At the same time, because RCC is a new type ... -

China Wholesale Round Pcb Suppliers - 8 Layer impedance ENIG PCB 6351 – Huihe

Half hole technology After the PCB is made in the half hole, the tin layer is set at the edge of the hole by electroplating. The tin layer is used as the protective layer to enhance the tear resistance and completely prevent the copper layer falling off from the hole wall. Therefore, the impurity generation in the production process of the printed circuit board is reduced, and the workload of cleaning is also reduced, so as to improve the quality of the finished PCB. After the production... -

China Wholesale Ic Circuit Board Manufacturers - 6 layer ENIG Impedance Control Heavy Copper PCB 15881 – Huihe

Functions of heavy copper PCB Heavy copper PCB has the best extension functions, is not limited by the processing temperature, high melting point can be used oxygen blowing, low temperature at the same brittle and other hot melt welding, but also fire prevention, belongs to the non-combustible material. Even in highly corrosive atmospheric conditions, copper sheets form a strong, non-toxic passivation protective layer. Difficulty in machining control of heavy copper PCB Thickness of copper PC... -

China Wholesale Prototype Pcb Assembly Services Pricelist - 4 Layer ENIG PCB 8329 – Huihe

Manufacturing technology of metallized half hole PCB The metallized half hole is cut in half after the round hole is formed. It is easy to appear the phenomenon of copper wire residue and copper leather warping in the half hole, which affects the function of the half hole and leads to the decrease of product performance and yield. In order to overcome the above defects, it shall be carried out according to the following process steps of metallized semi-orifice PCB 1. Processing half hole... -

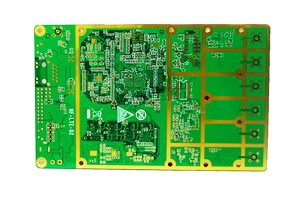

China Wholesale Custom Pcb Board Quotes - 8 Layer ENIG Impedance Control PCB – Huihe

Impedance is the combination of capacitance and inductance to hinder the circuit under high frequency signal. Impedance is an AC characteristic, which means it is frequency dependent. In the case of transmitting high-frequency signals, the controlled impedance helps to ensure that there is no significant attenuation of the signal during transmission. In essence, the controlled impedance means that the material characteristics of the substrate match the characteristics of the line / dielectric... -

China Wholesale Laser Circuit Board Quotes - 6 layer ENIG Heavy Copper PCB 15202 – Huihe

Crack problem of inner thick brazing pad The demand for heavy copper PCB is increasing, and the inner layer pads are getting smaller and smaller. The problem of pad cracking often occurs during PCB drilling (mainly for large holes above 2.5mm). There is little room for improvement in the material aspect of this kind of problem. The traditional improvement method is to increase the pad, increase the peeling strength of the material, and reduce the drilling rate, etc. Based on the analysis... -

China Wholesale Multilayer Flex Circuits Factories - 6 layer ENIG impedance control PCB – Huihe

How to improve the lamination quality of multilayer PCB? PCB has developed from single side to double side and multilayer, and the proportion of multilayer PCB is increasing year by year. The performance of multilayer PCB is developing to high precision, dense and fine. Lamination is an important process in multilayer PCB manufacturing. The control of lamination quality is becoming more and more important. Therefore, in order to ensure the quality of multilayer laminate, we need to have ... -

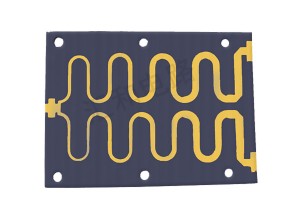

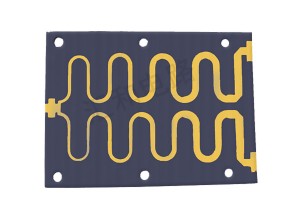

China Wholesale Redboard Pcb Manufacturers - 2 Layer F4B OSP PCB – Huihe

Effect of different types of copper foil on electrical properties In the design of high-frequency PCB, designers usually pay more attention to the dielectric constant (DK) and tangent loss (DF) of PCB when selecting materials, and only pay attention to the thickness of copper foil when selecting copper foil, which is easy to ignore the influence of different types of copper foil roughness on the electrical properties of products. SEM analysis of the micro morphology of different types of copp... -

China Wholesale Silkscreen Circuit Board Quotes - 8 Layer ENIG via-in-pad PCB 16081 – Huihe

Resin plugging process 1. Definition Resin plugging process refers to the use of resin to plug the buried holes in the inner layer, and then press, which is widely used in high-frequency board and HDI board; it is divided into traditional screen printing Resin Plugging and vacuum resin plugging. Generally, the production process of the product is traditional screen printing resin plug hole, which is also the most common process in the industry. 2. Process Pre process — drilling resin hole — e...