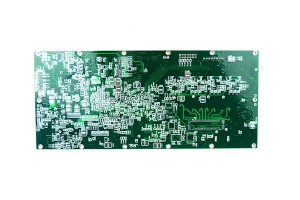

10 Layer High Density ENIG Multilayer PCB

Advantages Of Multilayer Printed Circuit Boards

While single-layer boards have their advantages, multilayer designs are more beneficial for some applications. For some devices, you may even need to have multiple layers. The benefits of more complex multilayer PCBs include:

1. For more complex projects:

More complex devices involving more circuits and components often require the use of multiple layers of PCBS. If more circuitry is needed than can fit on a single board, you can increase the space by adding layers. Having multiple boards ensures there is plenty of room for connections, making it ideal for more advanced devices. Devices with many different uses and advanced features, such as smartphones, require this level of complexity.

3. Increased power:

Multilayer PCBs are more powerful than less complex designs due to their increased circuit density. They have higher operational capability and can run at higher speeds, which is often necessary for advanced equipment, they power and allow for improved performance.

5. Smaller size and lighter weight:

Multilayer PCBs achieve this enhanced durability while still maintaining a relatively small size and lower weight. Because they are stacked on top of each other, you can cram more functionality into a more compact space than other boards. Smaller size also means lighter weight. A single layer board must be quite large to match the function of a multi-layer board. You can even use multiple monolayers to match it, but this will also increase the size and weight of the final product.

2. High quality:

Multilayer boards require more planning and intensive production processes, so they are generally of higher quality than other types of boards. Designing and producing these boards requires more skill and more advanced tools than simple components do, increasing the likelihood that you will get a high quality product. Many of these designs include advanced control impedance features and EMI shielding, further improving performance.

4. Increased durability:

Having more layers means the board is thicker and, therefore, more durable than single-sided PCBs. This is another reason why it is preferable to add functionality through additional layers to increase the dimension of a single layer. This enhanced durability means boards can withstand harsher conditions and generally last longer.

6. Single connection point:

Using multiple PCB components requires multiple connection points. Multilayer panels, on the other hand, are designed to work with just one connection point, thus simplifying the design of electronics and further reducing weight. When deciding whether to use multiple single panels or just one multilayer printed circuit board, multilayer boards are often the best choice.ger.

Multilayer Printed Circuit Board Applications

With the development of technology, multilayer PCB is becoming more and more common. The complex functionality and smaller size of many of today's electronic devices require the use of multiple layers on their circuit boards. Many devices across industries use multilayer boards, especially those with multiple and more complex functions.

Multilayer printed circuit boards are found in many computer components, including motherboards and servers. This type of circuit board is used in computer devices from laptops and tablets to smartphones and smartwatches. Smartphones typically require about 12 layers. Systems that allow electronic devices such as smartphones, laptops and GPS devices to operate, such as cell towers and satellite technology, also include multilayer panels because they require advanced features.

Not as complex as smartphones and cell towers, but too complex for single-sided printed circuit boards typically use four to eight layers. Examples of such products include household products, such as microwave ovens and air conditioners, which increasingly make use of multiple layers of technology.

Medical devices also often run on boards with more than three layers because they require reliability, small size, and lightweight design. Multilayer printed circuit boards are found in X-ray machines, heart monitors, CAT scanning devices, and many other applications.

The automotive and aerospace industries are also increasingly using electronic components that need to be durable and lightweight, making this type of PCB a good fit. These components must be able to withstand wear, heat and other harsh conditions. These boards are used in on-board computers, GPS systems, engine sensors, headlight switches and more.

High - level PCB is also the industrial standard. An increasing number of industrial machines are equipped with computerized components, often with sensors, controllers, and other components that require PCBS. Due to the harsh conditions of many industrial facilities, this equipment requires advanced functionality, reliability and durability.

For similar reasons, multilayer PCBS play a role in many military applications, weather analysis equipment, alarm systems, atom smashers, and many other types of electronic equipment.