Quality Inspection for Polyimide Pcb - 8 Layer ENIG Impedance Control Heavy Copper PCB – Huihe

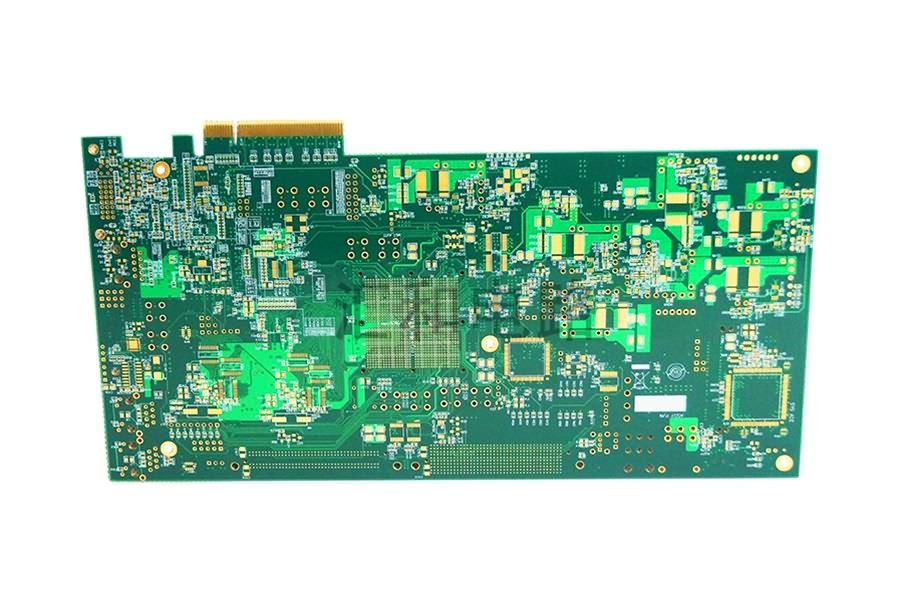

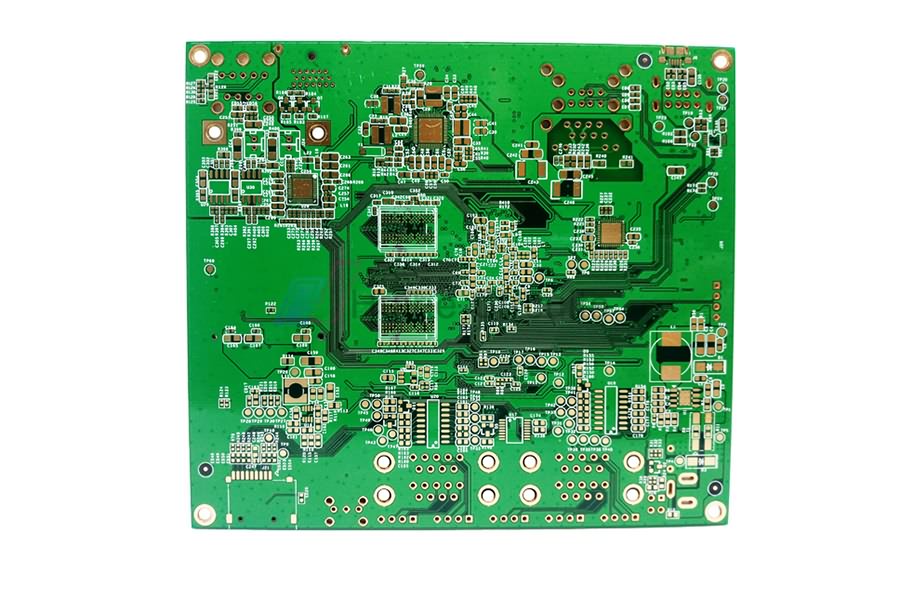

Quality Inspection for Polyimide Pcb - 8 Layer ENIG Impedance Control Heavy Copper PCB – Huihe Detail:

Thin Core Heavy Copper PCB Copper Foil Choice

The most concerned problem of heavy copper CCL PCB is the pressure resistance problem, especially the thin core heavy copper PCB (thin core is medium thickness ≤ 0.3mm), the pressure resistance problem is particularly prominent, thin core heavy copper PCB will generally choose RTF copper foil for production, RTF copper foil and STD copper foil main difference is the length of the wool Ra is different, RTF copper foil Ra is significantly less than STD copper foil.

The wool configuration of copper foil affects the thickness of the substrate insulation layer. With the same thickness specification, the RTF copper foil Ra is small, and the effective insulation layer of the dielectric layer is obviously thicker. By reducing the wool coarsening degree, the pressure resistance of the heavy copper of the thin substrate can be effectively improved.

Heavy Copper PCB CCL And Prepreg

Development and promotion of HTC materials: copper not only has good processability and conductivity, but also has good thermal conductivity. The use of heavy copper PCB and the application of HTC medium is gradually becoming the direction of more and more designers to solve the problem of heat dissipation. The use of HTC PCB with heavy copper foil design is more conducive to the overall heat dissipation of electronic components, and has obvious advantages in cost and process.

Equipment Display

PCB Automatic Plating Line

PCB PTH Line

PCB LDI

PCB CCD Exposure Machine

Factory Show

PCB Manufacturing Base

Admin Receptionist

Meeting Room

General Office

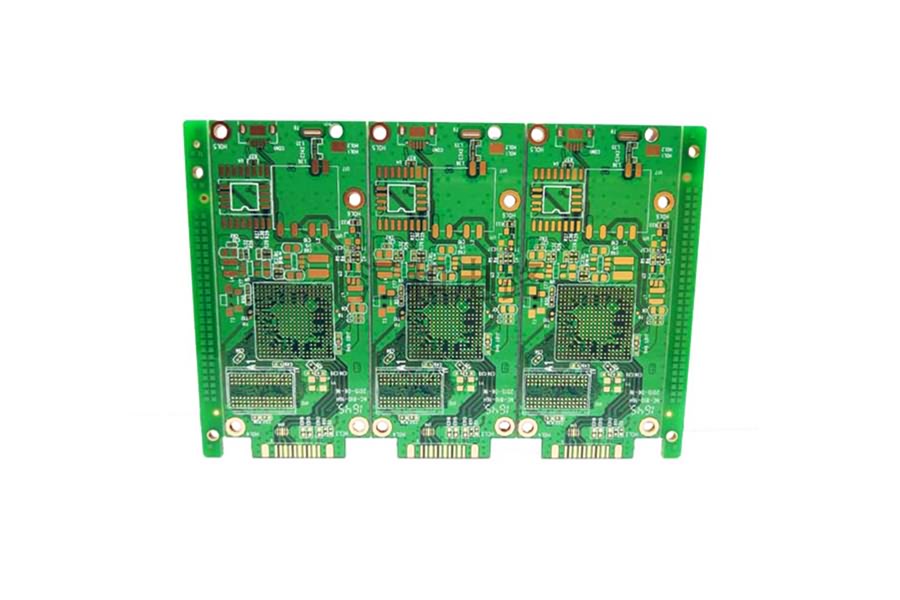

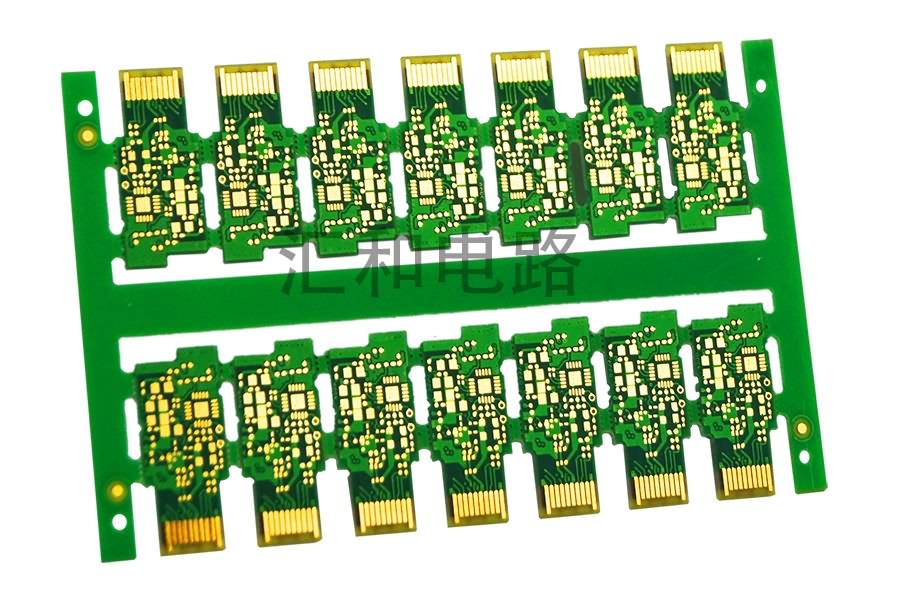

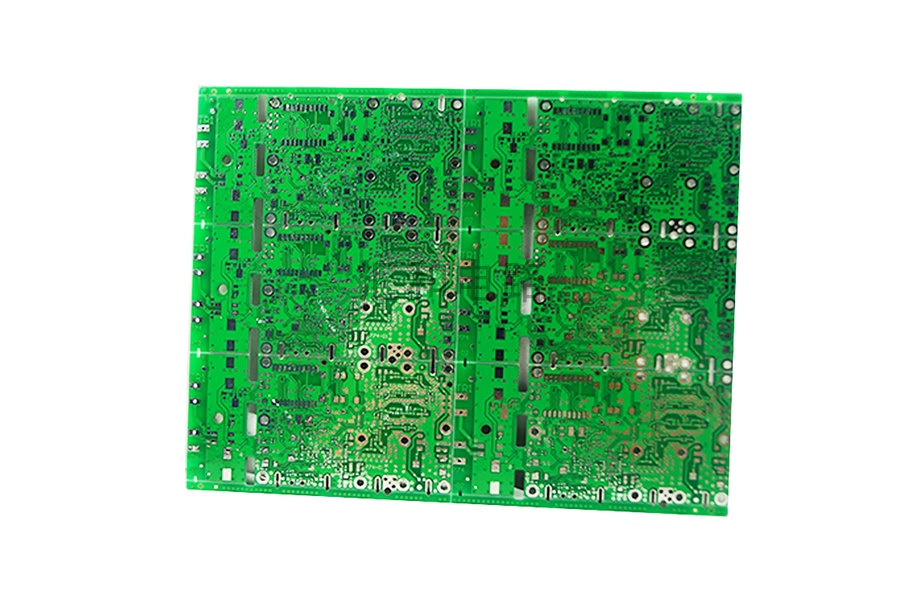

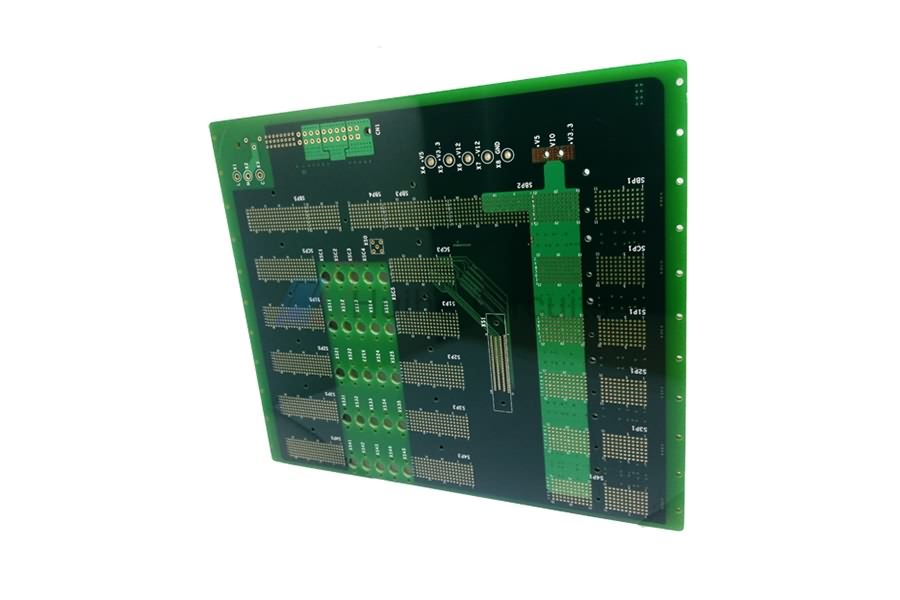

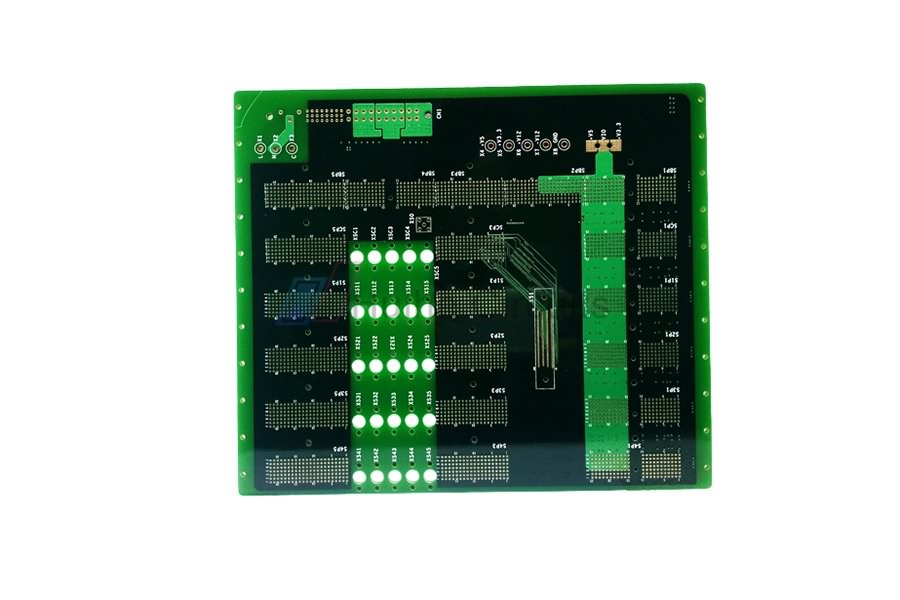

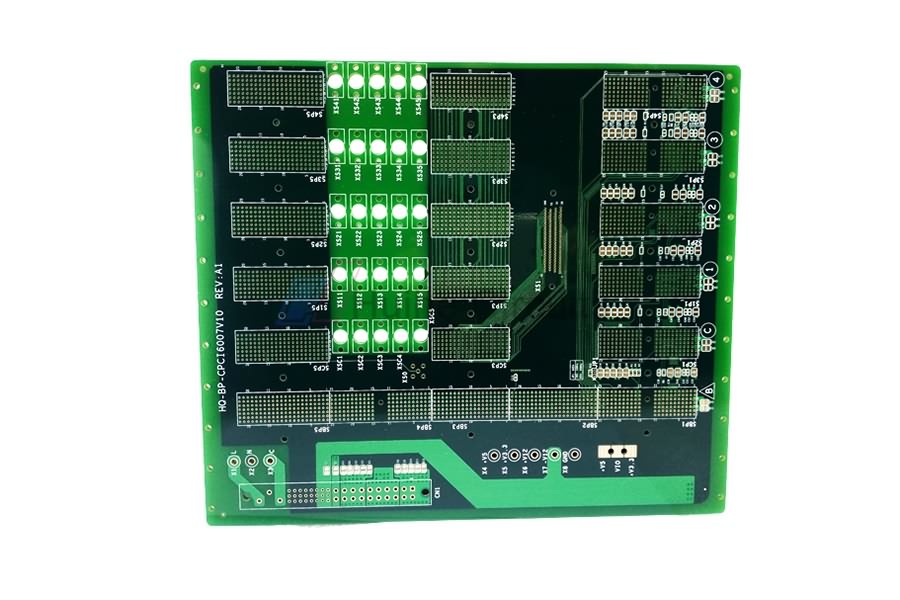

Product detail pictures:

Related Product Guide:

In the past few years, our business absorbed and digested advanced technologies both equally at home and abroad. In the meantime, our company staffs a group of experts devoted to your advancement of Quality Inspection for Polyimide Pcb - 8 Layer ENIG Impedance Control Heavy Copper PCB – Huihe , The product will supply to all over the world, such as: Malta, Buenos Aires, Slovakia, Our Company has professional engineers and technical staff to answer your questions about maintenance problems, some common failure. Our product quality assurance, price concessions, any questions about the products, Please feel free to contact us.

This company has a lot of ready-made options to choose and also could custom new program according to our demand, which is very nice to meet our needs.