China Wholesale Speaker Circuit Board Pricelist - 6 layer ENIG Heavy Copper PCB – Huihe

China Wholesale Speaker Circuit Board Pricelist - 6 layer ENIG Heavy Copper PCB – Huihe Detail:

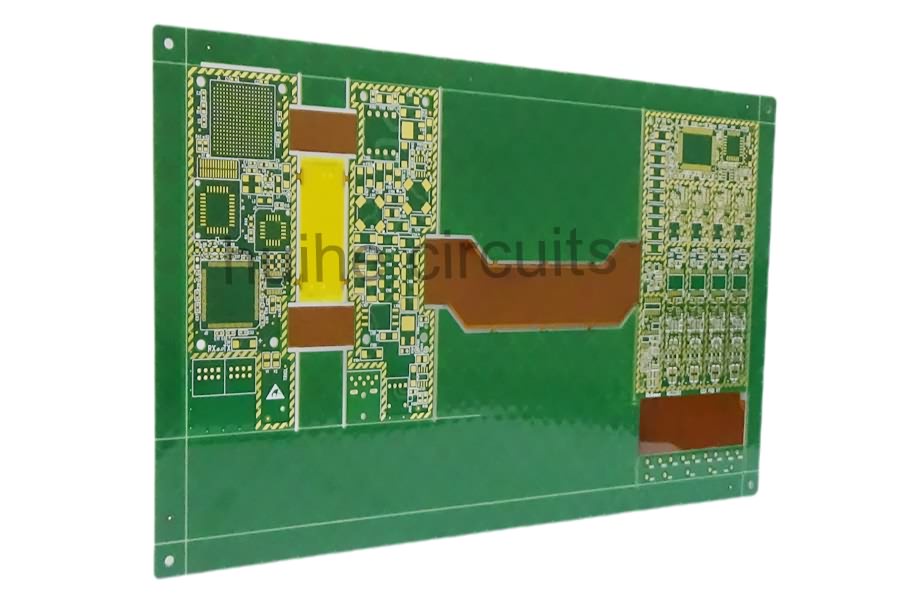

Heavy copper PCB is a layer of copper foil bonded on glass epoxy substrate of printed circuit board. When the thickness of finished copper is more than or equal to 2oz, it is defined as heavy copper PCB. heavy copper PCB has the best extensibility and is not limited by processing temperature. Even in extremely corrosive atmosphere, copper PCB will form a strong and non-toxic passivation protection layer. heavy copper PCB is widely used in various home appliances, high-tech products, military, medical and other electronic equipment. The application of heavy copper PCB makes the circuit board, the core component of electronic equipment products, have longer service life. At the same time, it is helpful to simplify the volume of electronic equipment.

Our advantage

The highest copper thickness of the sample is 8oz, and the copper thickness is 6oz in mass production

Introduce high precision equipment of PCB industry year by year to ensure excellent PCB process capability

Implement lean production, effectively monitor the production progress and improve the delivery rate.

Difficulties in manufacturing heavy copper PCB

1. In the process of etching, if the etching is not clean, the pressure will not reach the standard, which will lead to short circuit of the circuit.

2. Thick copper plate is easy to foaming agent in the process of solder mask ink manufacturing.

3. The scrap rate of thick copper PCB is the highest in the drilling process, the hole thickness and the nail head are the highest.

4. In the process of pressing, it is easy to appear problems such as insufficient glue filling, too much flowing glue, uneven thickness and voids.

Equipment display

Automatic Plating Line

PTH line

LDI

CCD Exposure Machine

Application

Communications

Security electronics

Railtransit

Our factory

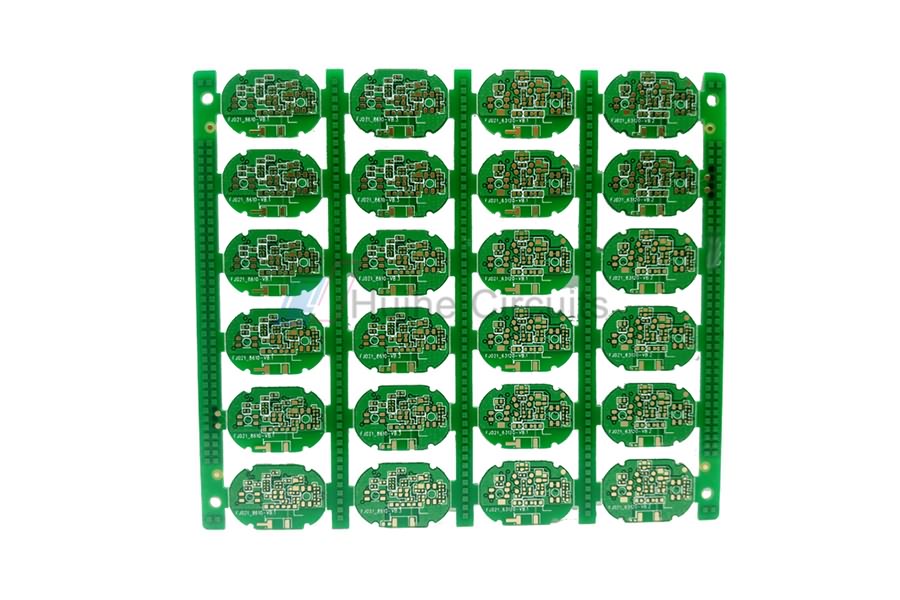

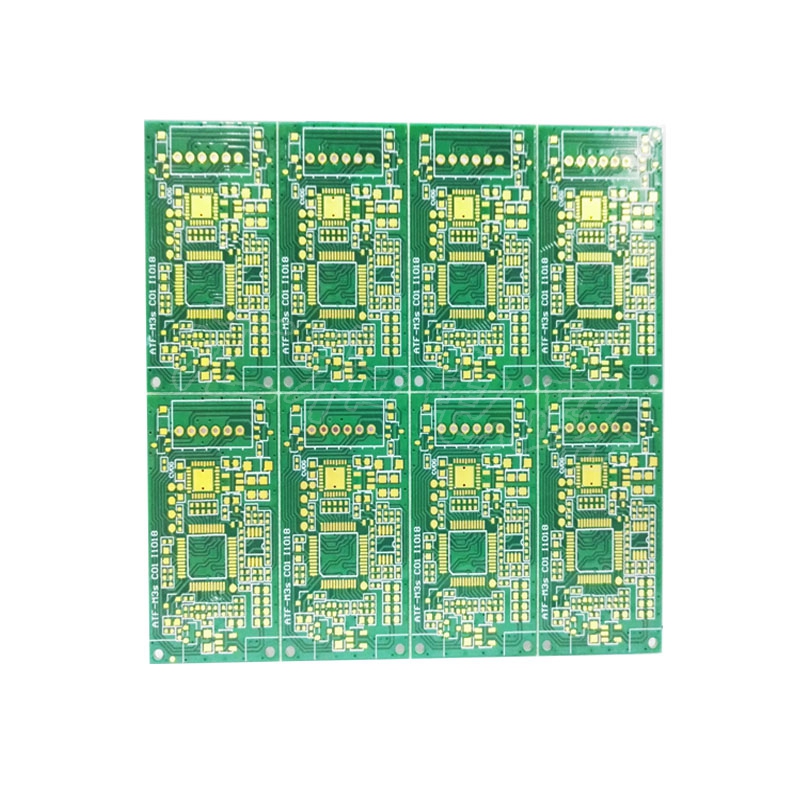

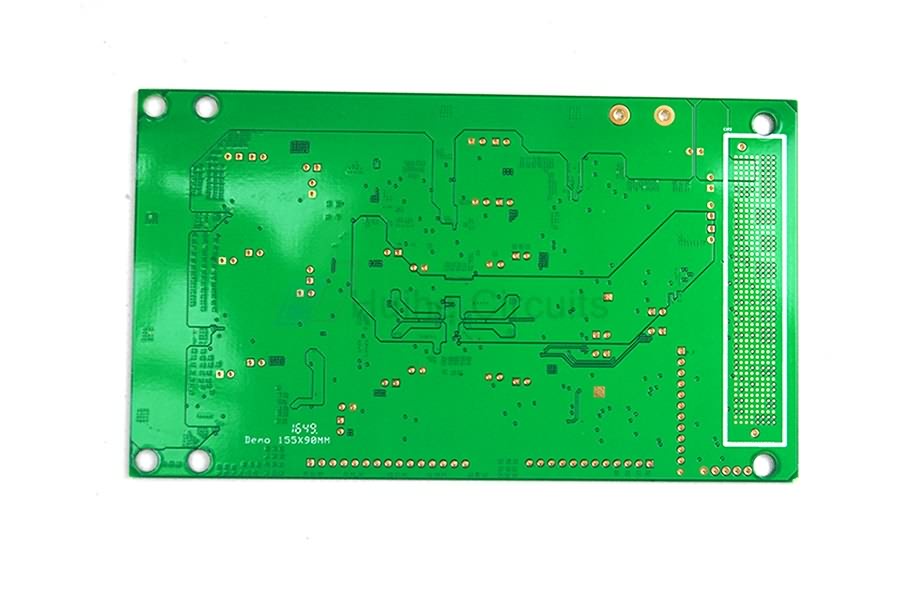

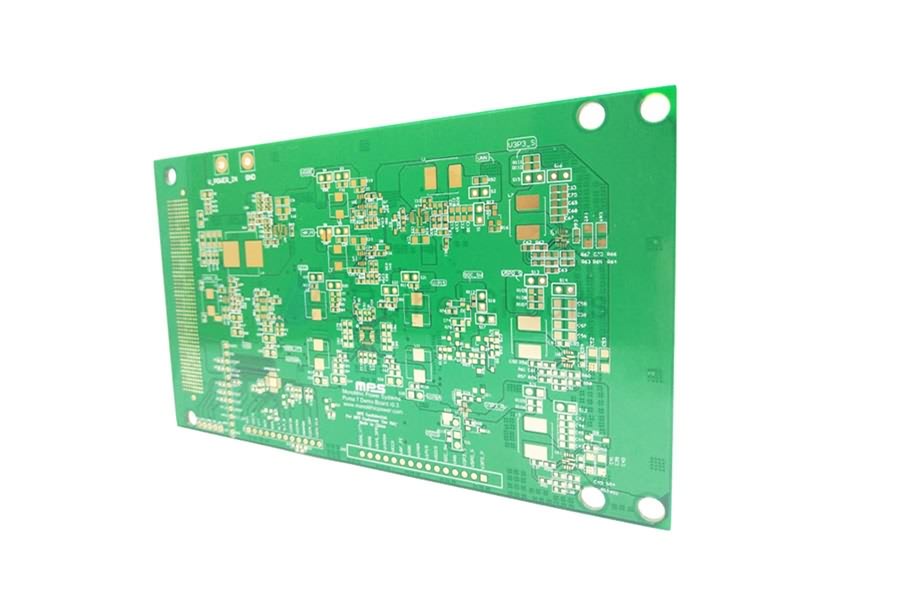

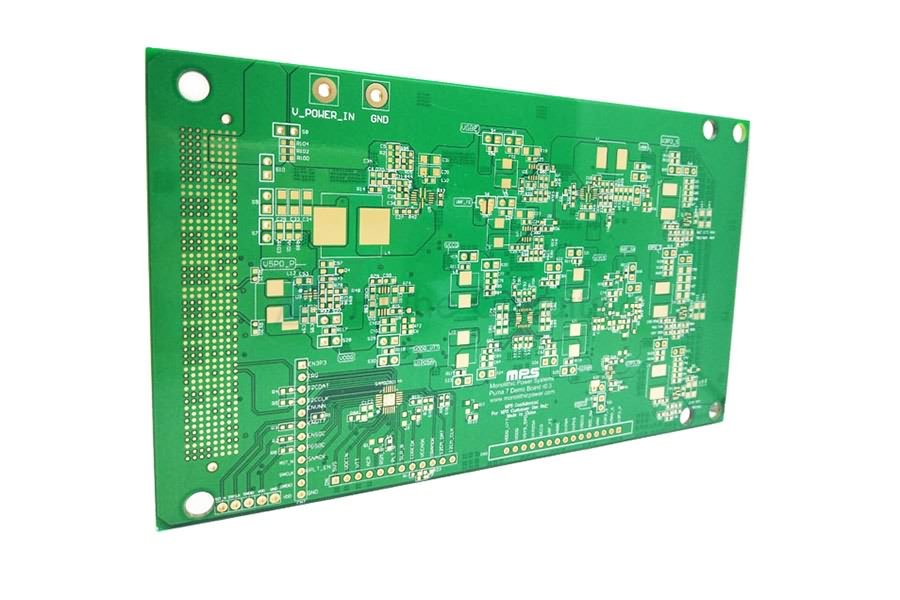

Product detail pictures:

Related Product Guide:

we are able to provide good quality items, aggressive rate and best shopper assistance. Our destination is "You come here with difficulty and we provide you with a smile to take away" for China Wholesale Speaker Circuit Board Pricelist - 6 layer ENIG Heavy Copper PCB – Huihe , The product will supply to all over the world, such as: Bandung, Peru, Comoros, We warmly welcome domestic and overseas customers to visit our company and have business talk. Our company always insists on the principle of "good quality, reasonable price, the first-class service". We have been willing to build long-term, friendly and mutually beneficial cooperation with you.

We have been appreciated the Chinese manufacturing, this time also did not let us disappoint,good job!