China Wholesale Pcb Producer Suppliers - 6 Layer ENIG Impedance Control Heavy Copper PCB – Huihe

China Wholesale Pcb Producer Suppliers - 6 Layer ENIG Impedance Control Heavy Copper PCB – Huihe Detail:

Functions Of Heavy Copper PCB

Heavy copper PCB has the best extension functions, is not limited by the processing temperature, high melting point can be used oxygen blowing, low temperature at the same brittle and other hot melt welding, but also fire prevention, belongs to the non-combustible material. Even in highly corrosive atmospheric conditions, copper sheets form a strong, non-toxic passivation protective layer.

Difficulty In Machining Control Of Heavy Copper PCB

Thickness of copper PCB brings a series of processing difficulties to PCB processing, such as the need for multiple etching, insufficient pressing plate filling, drilling inner layer welding pad cracking, hole wall quality is difficult to guarantee and other problems.

1. Etching difficulties

With the increase of copper thickness, the side erosion will become more and more large due to the difficulty of exchange of potion.

2. Difficulty in laminating

(1) with the increase of copper thick, dark line clearance, under the same rate of residual copper, resin filling quantity should be increased, then you need to use more than one and a half curing to meet fill glue problem: because of the need to maximize the resin filling line clearance, in areas such as the rubber content is high, the resin curing liquid half piece do heavy copper laminate is the first choice. The semi-cured sheet is usually chosen for 1080 and 106. In the inner layer design, copper points and copper blocks are laid in the copper-free area or the final milling area to increase the residual copper rate and reduce the pressure of glue filling.

(2) The increase in the use of semi-solidified sheets will increase the risk of skateboards. The method of adding rivets can be adopted to strengthen the degree of fixation between core plates. As the copper thickness becomes larger and larger, resin is also used to fill the blank area between the graphs. Because the total copper thickness of the heavy copper PCB is generally more than 6oz, the CTE match between the materials is particularly important [such as copper CTE is 17ppm, fiberglass cloth is 6PPM-7ppm, resin is 0.02%. Therefore, in the process of PCB processing, the selection of fillers, low CTE and T high PCB is the basis to ensure the quality of heavy copper (power) PCB.

(3) As the thickness of copper and PCB increases, the more heat will be needed in lamination production. The actual heating rate will be slower, the actual duration of the high temperature section will be shorter, which will lead to insufficient resin curing of the semi-cured sheet, thus affecting the reliability of the plate; Therefore, it is necessary to increase the duration of the laminated high temperature section to ensure the curing effect of the semi-cured sheet. If the semi-cured sheet is insufficient, it leads to a large amount of glue removal relative to the core plate semi-cured sheet, and the formation of a ladder, and then the hole copper fracture due to the effect of stress.

Equipment Display

PCB Automatic Plating Line

PCB PTH Line

PCB LDI

PCB CCD Exposure Machine

Factory Show

PCB Manufacturing Base

Admin Receptionist

Meeting Room

General Office

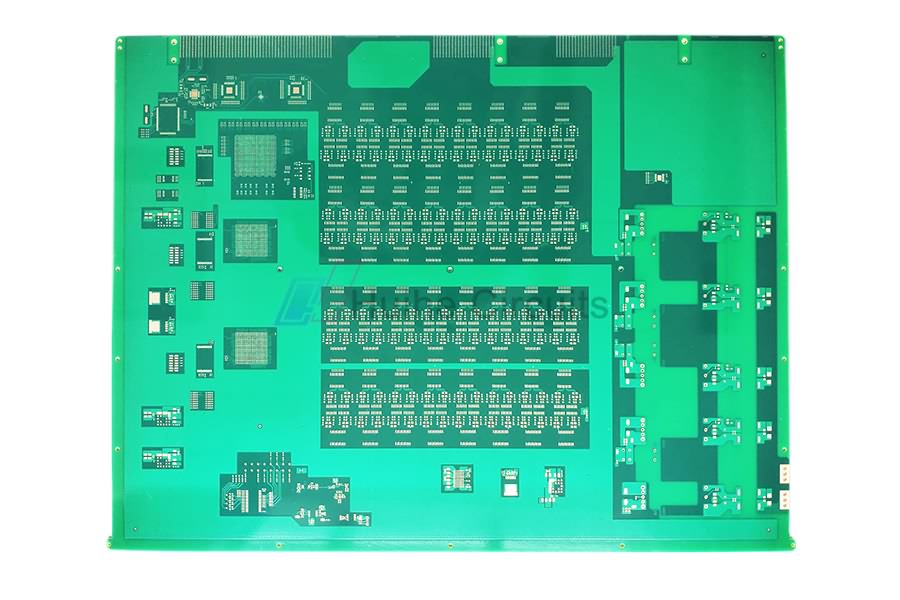

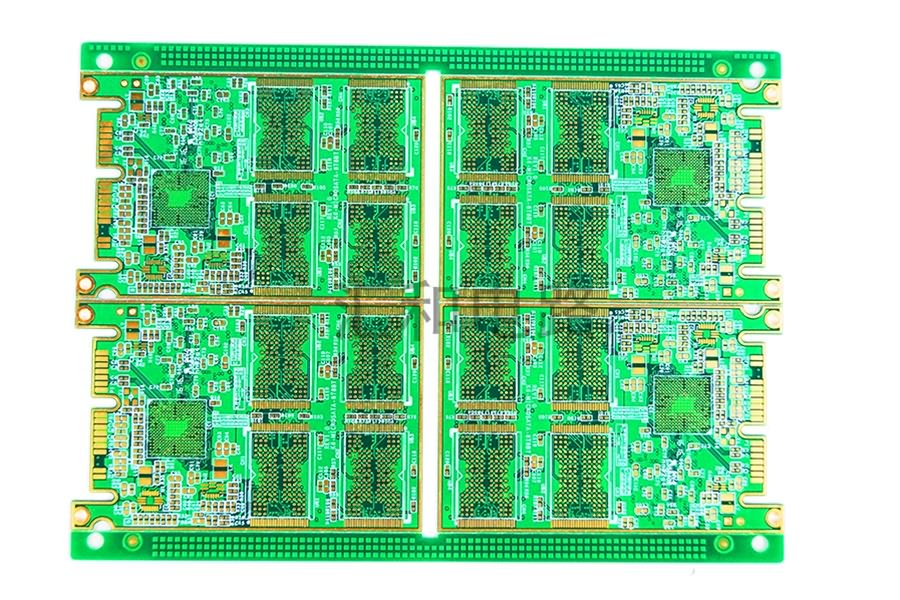

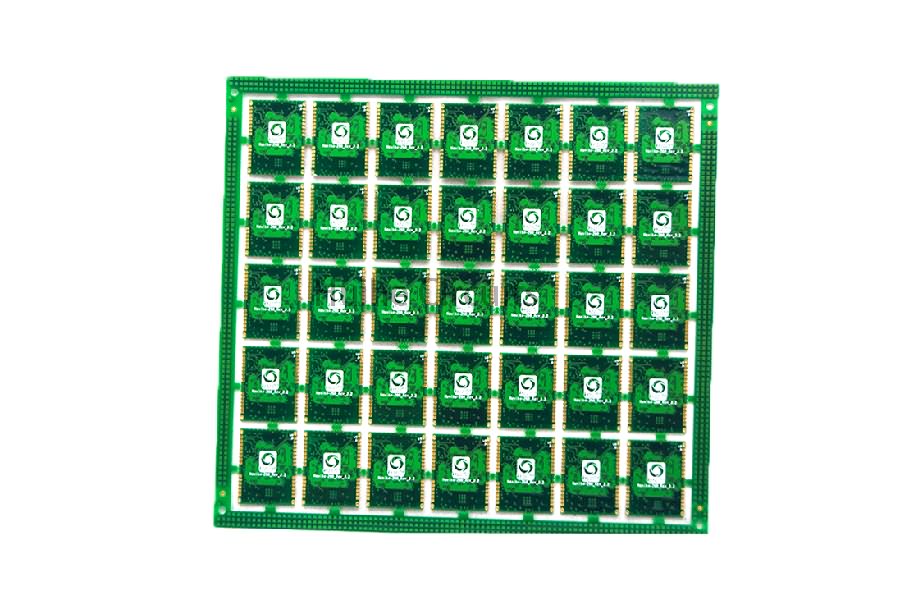

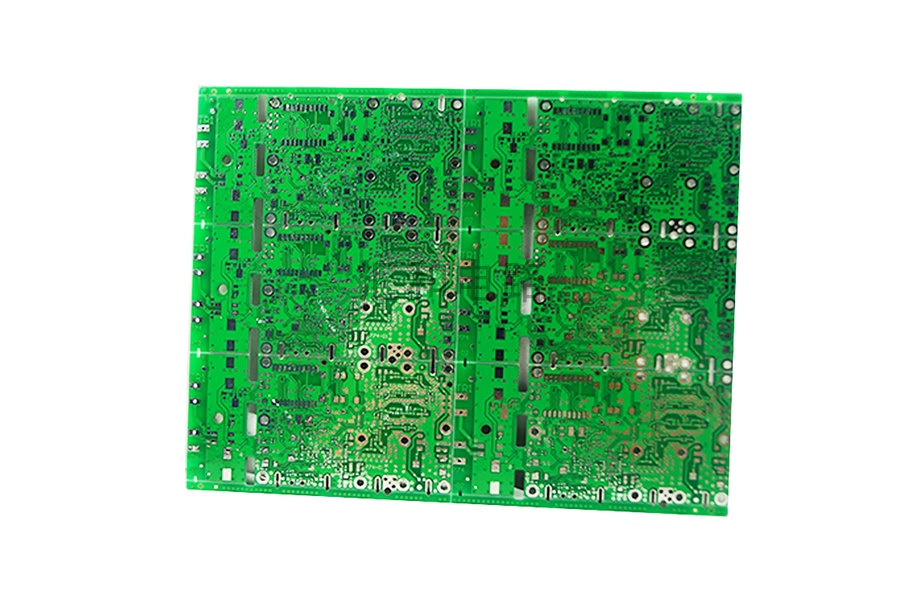

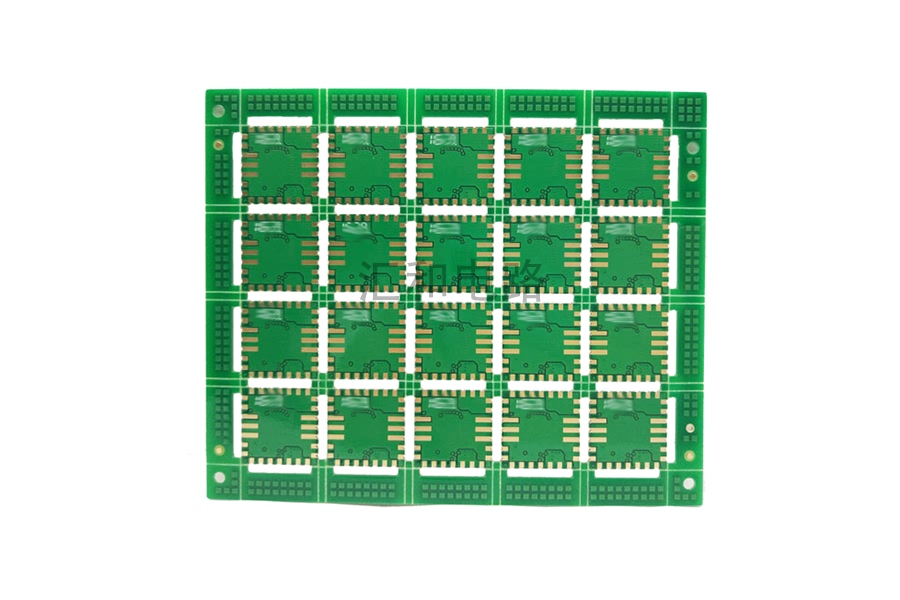

Product detail pictures:

Related Product Guide:

Our advantages are reduced prices,dynamic product sales workforce,specialized QC,solid factories,superior quality services for China Wholesale Pcb Producer Suppliers - 6 Layer ENIG Impedance Control Heavy Copper PCB – Huihe , The product will supply to all over the world, such as: UAE, Israel, Brisbane, Our company offers the full range from pre-sales to after-sales service, from product development to audit the use of maintenance, based on strong technical strength, superior product performance, reasonable prices and perfect service, we'll continue to develop, to deliver the high-quality items and services, and promote lasting cooperation with our customers, common development and create a better future.

The factory can meet continuously developing economic and market needs, so that their products are widely recognized and trusted, and that's why we chose this company.