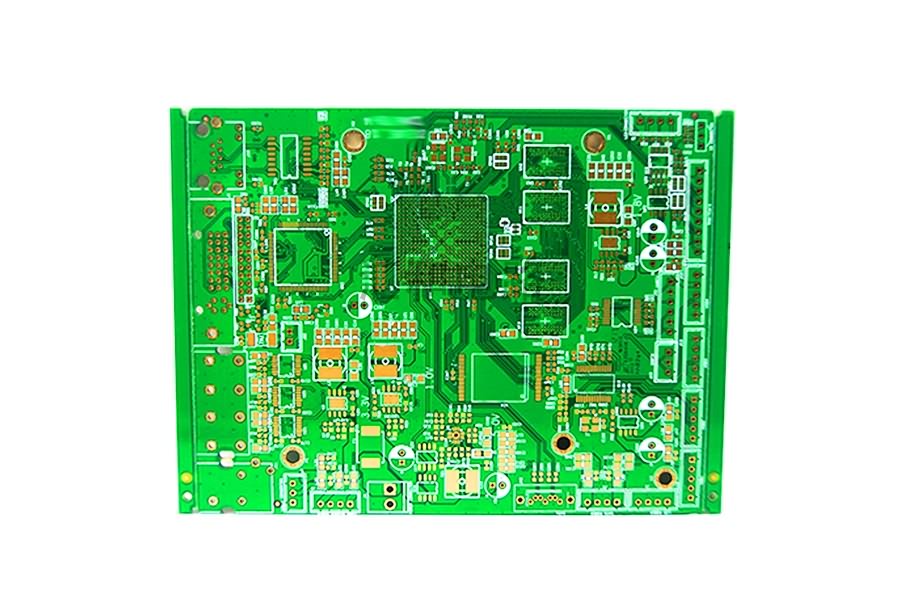

China Wholesale Pcb Order Factories - 6 Layer ENIG via-in-pad PCB 16842 – Huihe

China Wholesale Pcb Order Factories - 6 Layer ENIG via-in-pad PCB 16842 – Huihe Detail:

The advantages and disadvantages of plugging and no plugging?

In terms of plug holes, they have the following advantages

1. the plug hole can prevent PCB through the wave soldering tin from the through hole through the component surface caused by short circuit; That is to say, within the scope of the wave soldering design area (generally the welding surface is 5mm or above) there is no hole or hole to do plug hole treatment.

2. The plug hole protects against possible short circuits caused by closely spaced devices such as BGA. This is the reason for the hole under the BGA to keep the hole in the design process. Because there is no plug hole, this is a case of short circuit.

3. avoid flux residue in the conduction hole;

4. After the surface mounting and component assembly of the electronics factory is completed, the PCB shall be vacuum absorbed and negative pressure formed on the test machine before completion:

5. prevent the surface solder paste into the hole caused by virtual welding, affect the installation; This point is most obvious in the heat dissipation pad with holes.

6. To prevent the wave soldering tin beads pop up, resulting in a short circuit.

7. The plug hole will be helpful to the SMT process.

From the perspective of no plug hole, there are the following advantages

1. Some VIA holes (through holes) are green oil Windows, because these holes are the test holes that the PROBE will contact.

2. The green oil plug hole cannot be 100% filled, so there may be chemical liquid stuck in the hole during the PCB manufacturing process, which may lead to corrosion. But do not plug can.

3. If the two-sided plug hole is used, it is easy to have bubbles in the middle, which will expand and burst in the SMT process.For example, the common graphics of the plug hole plate describe the problem, the bubble problem, the tin bead problem, the oil problem, the bursthole problem, the light transmission crack problem in the plug hole are likely to appear.

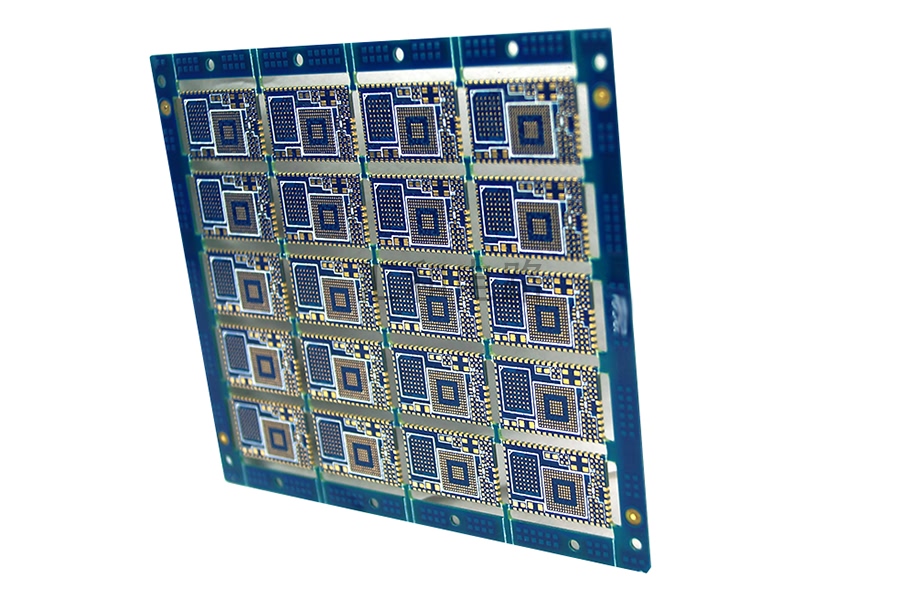

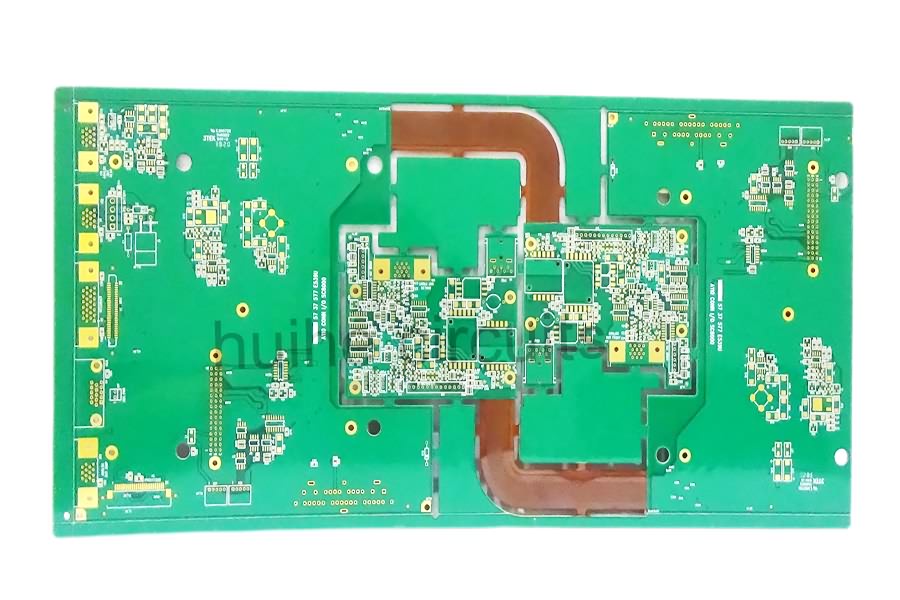

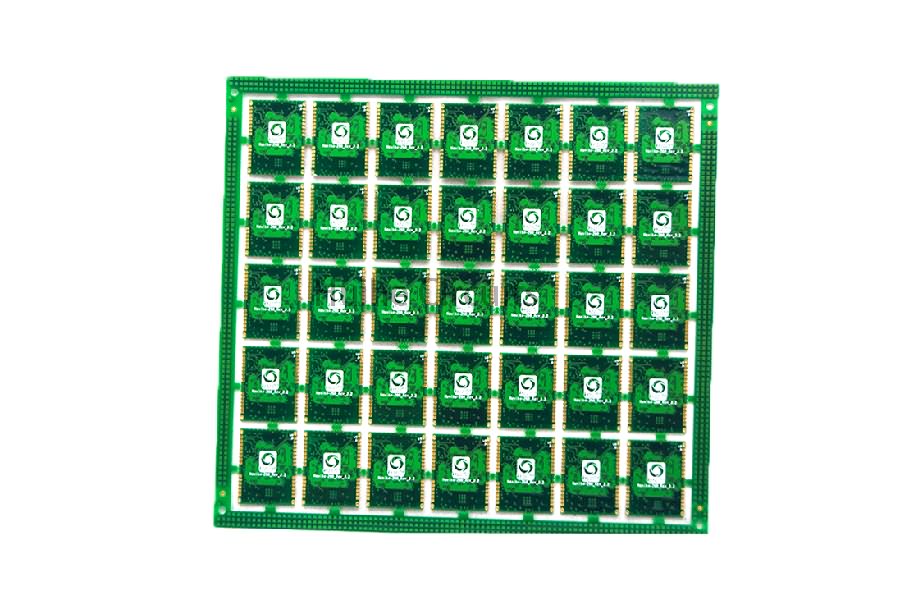

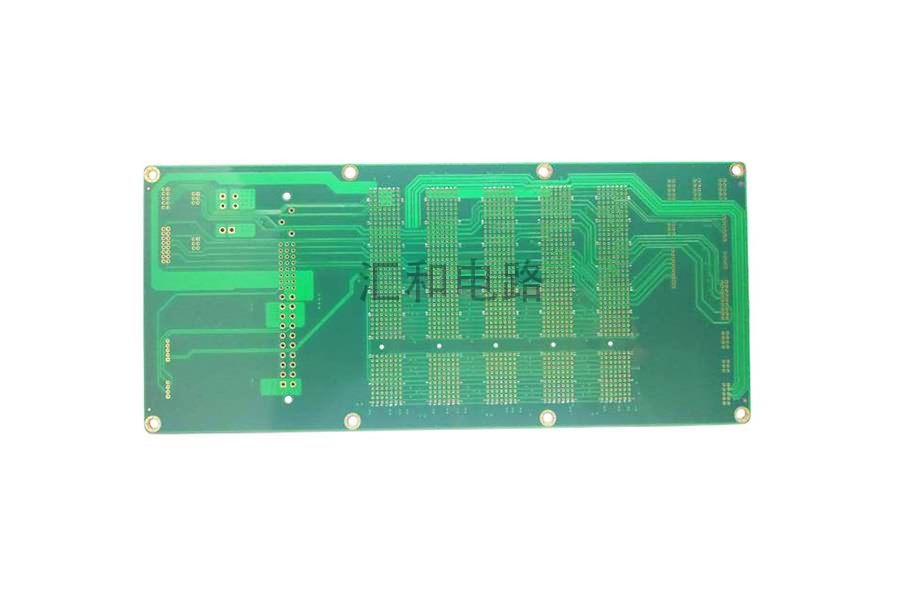

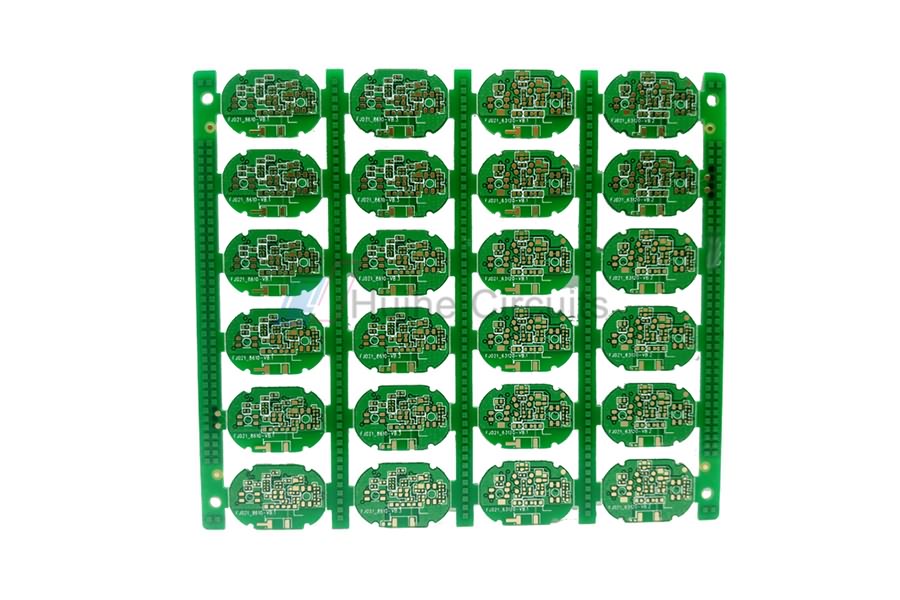

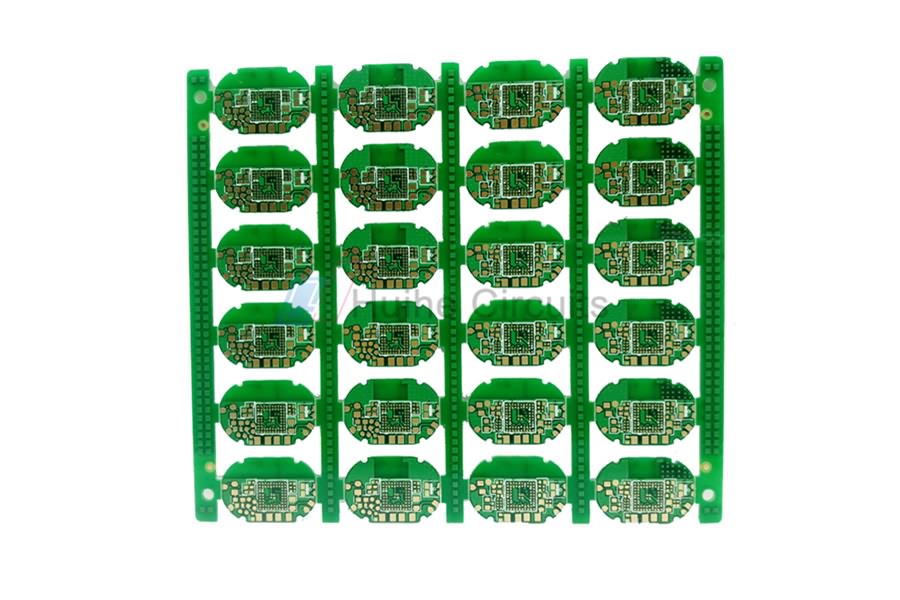

Product detail pictures:

Related Product Guide:

With dependable high quality approach, great reputation and excellent customer support, the series of products and solutions produced by our firm are exported to lots of countries and regions for China Wholesale Pcb Order Factories - 6 Layer ENIG via-in-pad PCB 16842 – Huihe , The product will supply to all over the world, such as: Turkey, America, Slovakia, High output volume, top quality, timely delivery and your satisfaction are guaranteed. We welcome all inquiries and comments. If you are interested in any of our products or have an OEM order to fulfill, please feel free to contact us now. Working with us will save you money and time.

The accounts manager made a detailed introduction about the product, so that we have a comprehensive understanding of the product, and ultimately we decided to cooperate.