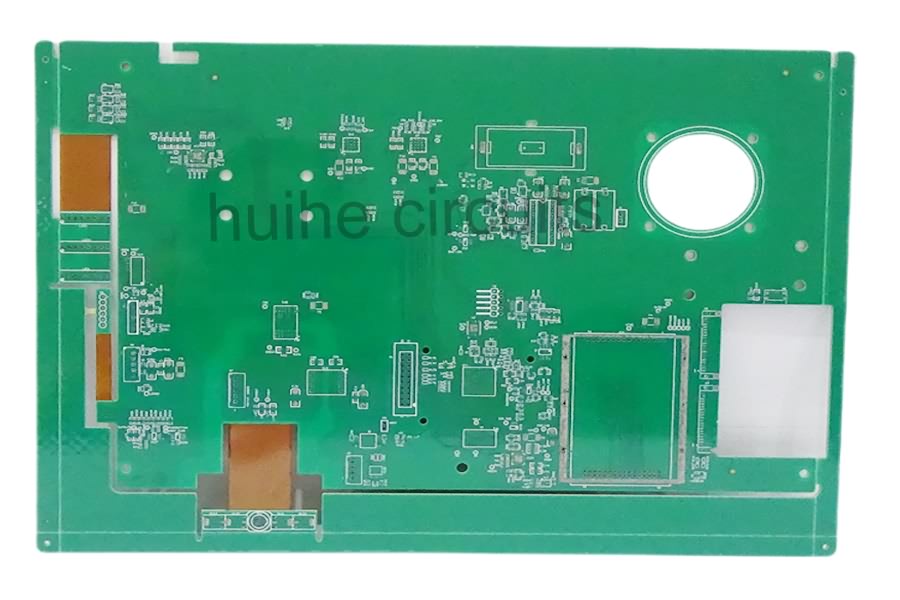

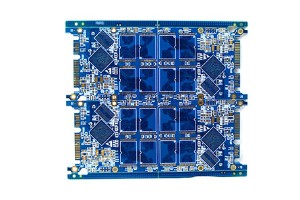

8 Layer HASL FPC+FR4 Rigid-Flex PCB

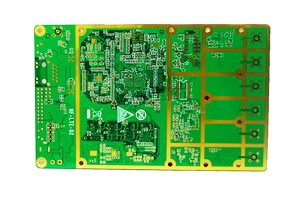

About Rigid-Flex PCB

The birth and development of FPC and PCB gave birth to the new product of Rigid-Flex PCB. Therefore, the combination of flexible PCB and Rigid PCB is a kind of PCB circuit board with FPC characteristics and PCB characteristics, which is formed by combining flexible circuit board and Rigid circuit board together according to relevant process requirements through pressing and other processes. Because Rigid-Flex PCB is the combination of FPC and PCB, the production of FPC and PCB should be equipped with FPC production equipment and PCB production equipment at the same time.

Processing Difficulties Of Rigid-Flex PCB

Flexible PCB part:

(1) Rigid PCB production equipment to produce Flexible PCB.Since the Flexible PCB material is soft and thin, the Flexible PCB passing through all horizontal lines must be carried by traction plate to avoid scrapping.

(2) The single chip treatment before lamination also has a great influence on interlayer alignment. Because polyimide materials are not resistant to strong alkali and swell in strong alkali solution, in the process of blackening and browning, the temperature and time should be appropriately reduced in strong alkaline processes such as degreasing, blackening and browning.

(3) Because the flexible sheet is easy to deform, the flatness before lamination is poor, and the resin fluidity of the adhesive sheet is much lower than that of the semi cured sheet used for lamination of the rigid plate. Therefore, in order to make the bonding piece and the single piece well combined and embedded in the fine line spacing, we choose to use the materials with good covering property as the laminated cushion materials, such as polypropylene film, PTFE, silicon The laminated quality of flexible board can be improved by rubber sheet

Rigid PCB part:

(1) The warp and weft direction of the glass cloth should be consistent, and the thermal stress and warpage should be eliminated during the pressing process.

(2) Rigid-Flex PCB pressure control. Due to the poor stability of soft board materials, it is necessary to complete the production of Flexible PCB and pressing PI covering film first, and then make the Rigid PCB according to its expansion and contraction coefficient.

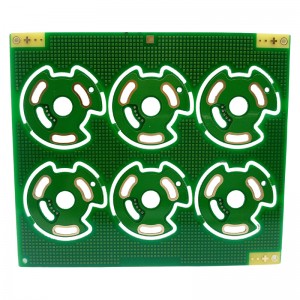

(3) For the processing of flexible window, there are usually milling and milling after cutting, but flexible processing should be carried out according to the structure and thickness of the Rigid-Flex PCB. If the flexible window is first milled, the accuracy of milling should be ensured, which can not affect welding or deflection greatly.

Advantage Of Rigid Flexible PCB Manufacturing

1.Implement lean production, effectively monitor the production progress and improve the delivery rate.

2.Professional Customization: to undertake proofing, batch PCB order demand

3.Complete product certification and factory system certification