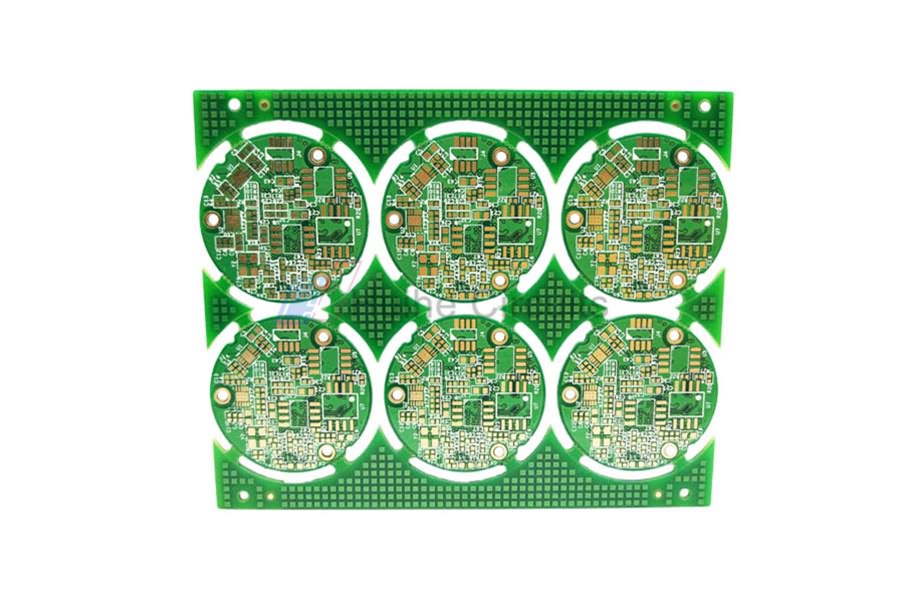

8 Layer ENIG FR4 Via-In-Pad PCB

The most difficult thing to control the plug hole in the via-in-pad is the solder ball or pad on the ink in the hole. Due to the necessity of using high density BGA (ball grid array) and the miniaturization of SMD chip, the application of in tray hole technology is more and more. Through the reliable through hole filling process, the in plate hole technology can be applied to the design and manufacture of high-density multilayer board, and avoid abnormal welding. HUIHE Circuits has been using via-in-pad technology for many years, and has an efficient and reliable production process.

Parameters Of Via-In-Pad PCB

|

Conventional products |

Special products |

Special products |

|

|

Hole filling standard |

IPC 4761 Type VII |

IPC 4761 Type VII |

- |

|

Min Hole Diameter |

200µm |

150µm |

100µm |

|

Minimum pad size |

400µm |

350µm |

300µm |

|

Max Hole Diameter |

500µm |

400µm |

- |

|

Maximum pad size |

700µm |

600µm |

- |

|

Minimum pin pitch |

600µm |

550µm |

500µm |

|

Aspect Ratio: Conventional via |

1:12 |

1:12 |

1:10 |

|

Aspect Ratio: Blind via |

1:1 |

1:1 |

1:1 |

Function Of Plug Hole

1.Prevent the tin from passing through the conduction hole through the component surface during wave soldering

2.Avoid flux residue in the through-hole

3.Prevent tin balls from popping out during wave soldering, resulting in short circuit

4.Prevent the surface solder paste from flowing into the hole, causing virtual welding and affecting the fitting

Advantages Of Via-In-Pad PCB

1.Improve heat dissipation

2.The voltage withstand capacity of vias is improved

3.Provide a flat and consistent surface

4.Lower parasitic inductance

Our Advantage

1. Own factory, factory area 12000 square meters, factory direct sales

2. The marketing team provides fast and high-quality pre-sales and after-sales services

3.Process-based processing of PCB design data to ensure that customers can review and confirm in the first time