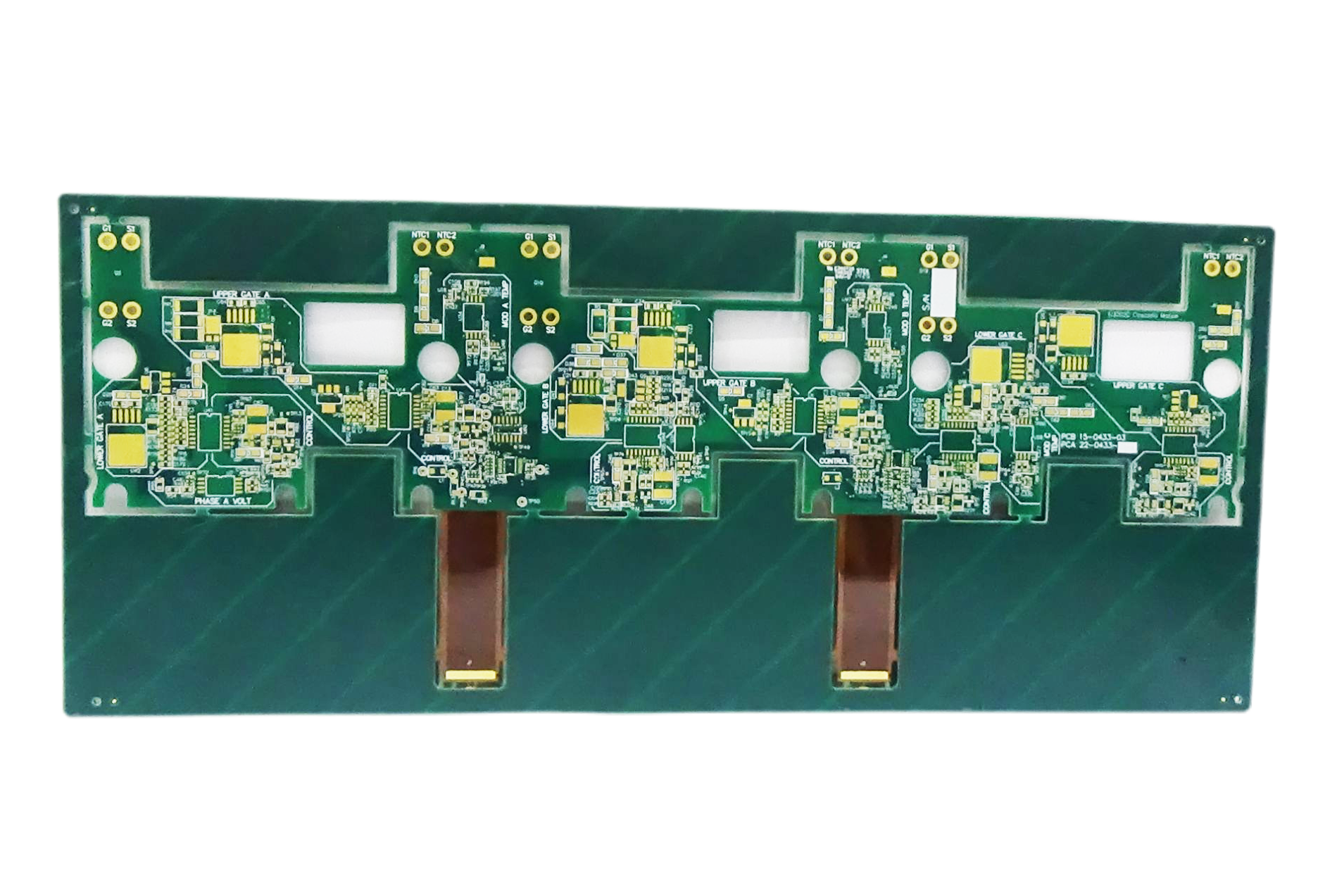

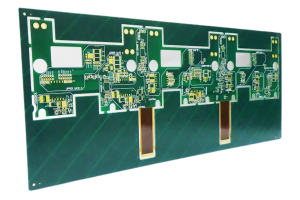

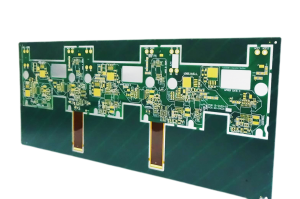

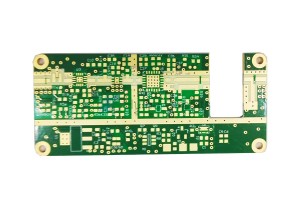

8 Layer ENIG Industrial Control Rigid Flex PCB

Rigid Flex PCB

Rigid flexible PCBs are an excellent choice for ultra-thin packaging requirements. Rigid and flexible printed circuit boards that can be folded or bent while retaining their shape. The rigid PCB is responsible for accommodating all components, while the flexible film connects the two rigid PCBs. With their ability to simplify electronic design, they offer additional functionality and improved electrical performance.

Rigid Flex PCB Process Capacity

| Items | Mass Production Capabilities | Prototyping Capabilities |

| Layers | 2 - 32 L | 2 - 20 L |

| Board thickness | 0.35-6.0mm | 0.35-5.0mm |

| Flexible thickness | 0.06-0.5mm | 0.07-0.5mm |

| Minimum line width | 0.05mm | 0.075mm |

| Minimum space | 0.05mm | 0.075mm |

| Impedance control tolerance | ± 10 % | ± 10 % |

| Special impedance tolerance | ± 3 % | ± 3 % |

| Flexible minimum width | 4mil | 5mil |

| Maximum size | 480 - 1000mm | |

| Outer copper thickness | 6 oz | |

| Inner copper thickness | 3 oz | |

| Mechanical minimum aperture | 0.1mm | |

| Laser minimum aperture | 0.075mm | |

| Maximum thickness to diameter ratio | 11:1 | |

| Hole distance to the conductor | below 8L 6mil;10L 8mil;more than 12L 10mil | |

| HDI type | 1+n+1;2+n+2 | |

| Rigid PCB | Sheng Yi, Hong Ren, Lian Mao, Lian Zhi | |

| Flexible PCB | Shengyi, Dupont, Panasonic, Taihong, Xinyang | |

| Materials type | FR4, Electrolytic Copper, Calendered Copper, PET, PI (Polyimide) | |

| Reinforcement type | PI,PET,FR4,SUS,PSA | |

| Surface finish | ENIG, silver, soft gold, nickel, palladium, tin, oxidation resistance, tin spray | |

| Process varieties | Rigid flex PCB, FPC, High tg PCB, Via in pad PCB, Sidestep PCB and other special technology | |

Benefits Of Rigid Flex PCB

Rigid flexible PCBs have various advantages. Some of these include:

Write your message here and send it to us