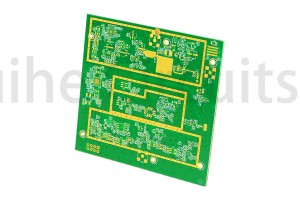

6 Layer ENIG RO4350+FR4 Mixed Lamination PCB

Mixed Lamination High Frequency PCB

The electrical, thermal and mechanical properties of high-frequency materials are different from those of conventional FR-4 materials. High frequency PCB has low dielectric constant Dk, low transmission delay, low loss factor Df and low dielectric loss.

The high-frequency microwave PCB board and RF board produced by HUIHE Circuit include 5G base station antenna circuit board, 4G intermodulation antenna circuit board, high-precision impedance circuit board, high-frequency high-speed mixed lamination PCB circuit board, high-precision phase shifter circuit board, high-power coupler circuit board, radar circuit board, which are commonly used in mobile communication, wireless base station, radar, automotive electronic anti-collision radar, 5g, new energy, medical treatment and mobile Mobile multimedia, radio and television transmitter, cable TV, wireless charging, RFID, etc, UAV image transmission and other fields. High frequency microwave PCB board and RF board are exported to North America, South America, Europe, Southeast Asia and other countries and regions.

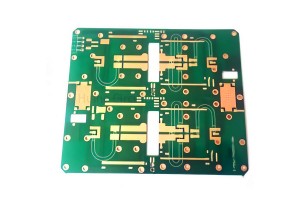

Mixed Lamination High Frequency PCB Materials

Rogers Materials is a proprietary braided glass reinforced hydrocarbon/ceramic material with the electrical properties of PTFE/braided glass and the manufacturability of epoxy/glass. Available in different configurations, Rogers comes in two fiberglass fabric styles, 1080 and 1674, all of which conform to the same laminate electrical specifications.

Rogers provides strict control over dielectric constants and low losses while using the same treatment as standard epoxy/glass at a fraction of the cost of traditional microwave laminates. Unlike teflon microwave materials, no special through-hole treatment or treatment procedures are required.

RO4003C material is non-brominated, not UL94V0 class. For applications or designs requiring ul94V0 flame rating, RO4835 and RO4350B plates meet this requirement.

RO4350B provides strict control over dielectric constant and low losses while using the same processing methods as standard epoxy/glass at a fraction of the cost of traditional microwave laminates. No special through-hole treatment or treatment procedures are required, such as ptfe microwave materials.

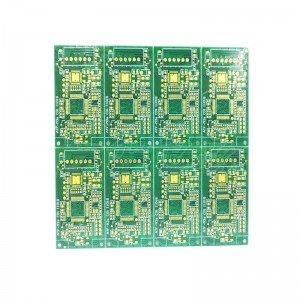

Advantages For Mixed Lamination PCB Manufacturing

01. Choose Rogers3003/4003/4350/5880B, Arlon,Taconic, F4B, teflon/PTFE materials, from the source to ensure the quality of the products

02. With high-frequency material supply, let your products win at the root

03. Rigorous quality control system effectively ensures product performance

04. Mature mixed laminated technology, to meet the special needs of high frequency PCB board

05. Fully automatic production equipment, to ensure the processing accuracy of high-frequency circuit board