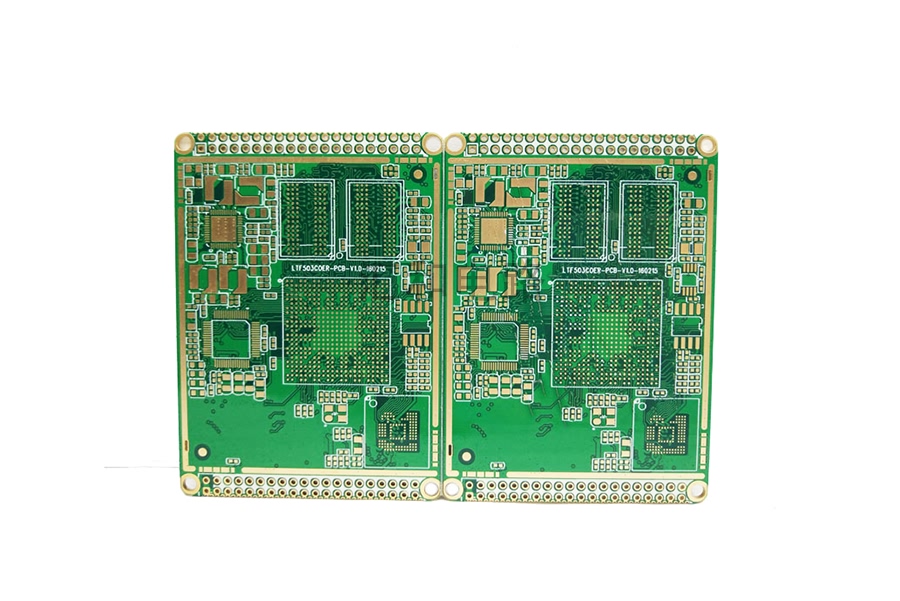

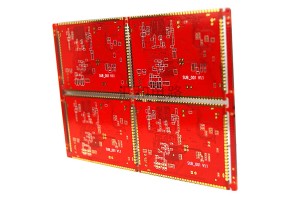

6 Layer ENIG Impedance Half Hole PCB

How To Identify A Half Hole In Your Design File ?

Half hole PCB is designed because of the structure of the device and circuit board plug-in A single or whole rowof device holes are directly added to the outline of the metalized half hole to ensure that half of the deviceholes are in the board and half are out of the board . The Gerber file should contain the following:

01.Line layer(GTL and GBL)

Half hole brazing pads are located at top and bottom

02.Weld barer layer(GTS and GBS)

Weld barnier opening at half hole position

03.Hole layer (TXT/DRL)

The hole location of each half hole

04.Mechanical/profile layer(GMU/GKO)

The profile should be centered through each half hole

About Metallized Half Hole PCB

The metallized half hole is a half hole at the edge of the plate and is electroplated. Metallized semi-holes are mainly used for the direct connection between plates. They are mainly used to weld together two printed circuit boards with circuit design technology. The whole system takes up much less space than a PCB system using a row pin connector.

Design Parameters Of Half Hole PCB

|

Min. Hole Diameter |

Minimum pad |

Minimum pad spacing |

The distance between window and green |

Minimum size of solder bridge |

Minimum pin pitch |

|

500µm |

900µm |

250µm |

50µm-75µm |

100µm |

1150µm |

How Are Metallized Half Hole PCBs Made?

First, electroplated through-holes are made on the edges of PCS or SETS (smaller units in production plate PNL), then the routing machine (milling machine) is used to remove half of the electroplated through-holes, leaving the other half half-holes.

Because copper is hard to work and is likely to cause the bit to break, special knives and higher plate speeds are needed to make the surface of the hole walls and edges smoother. Each half-well is then inspected by a semi-finished product inspection station.

The minimum diameter of the half-holes that can be manufactured by the HUIHE Circuits shall be 0.5 mm and the half-holes shall be at least 0.5 mm apart. If you need to make smaller half-hole aperture, please contact our customer service staff to discuss the feasibility of the solution.

When placing a purchase order for half hole plates with HUIHE Circuits, please communicate the details of half hole PCBs with HUIHE Circuit's technical engineers to ensure that you receive a cost-effective manufacturing solution.

Our Advantages For Half Hole PCB

1. Own factory, factory area 12000 square meters, factory direct sales

2.20+ core technical personnel with more than 10 years of experience, proficient in industry standards and process quality.

3.Advanced equipment: automatic copper deposition / electroplating line, LDI / CCD exposure machine and other equipment to produce high quality and high reliability products