6 Layer ENIG Impedance Control PCB

About Multilayer PCB

With the increasing complexity of circuit design, in order to increase the area of wiring, multilayer PCB can be used. Multilayer board is a PCB that contains multiple working layers. In addition to the top and bottom layers, it also includes signal layer, middle layer, internal power supply and ground layer.

The number of layers of PCB represents that there are several independent wiring layers. Generally, the number of layers is even and includes the outermost two layers. Because it can make full use of multilayer board to solve the problem of electromagnetic compatibility, it can greatly improve the reliability and stability of the circuit, so the application of multilayer board is more and more widely.

PCB Transaction Process

A Variety Of PCB Processes

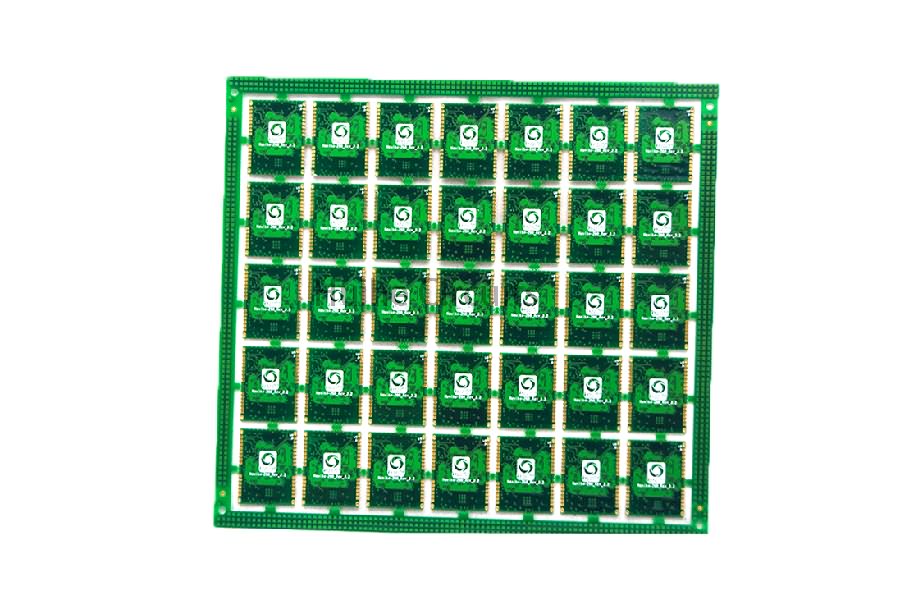

Multilayer PCB

Minimum line width and line spacing 3/3mil

BGA 0.4pitch, minimum hole 0.1mm

Used in industrial control and consumer electronics

Half Hole PCB

There is no residual or warping of copper thorn in half hole

The child board of the mother board saves connectors and space

Applied to Bluetooth module, signal receiver

Blind Buried Via PCB

Use micro-blind holes to increase the line density

Improve radio frequency and electromagnetic interference, heat conduction

Apply to servers, mobile phones, and digital cameras

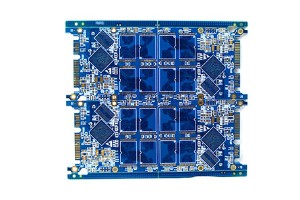

Via-in-Pad PCB

Use electroplating to fill holes/resin plug holes

Avoid solder paste or flux flowing into pan holes

Prevent holes with tin beads or ink pad lead to weld

Bluetooth module for consumer electronics industry

Write your message here and send it to us