4 Layer ENIG RO4003+AD255 Mixed Lamination PCB

RO4003C Rogers High Frequency PCB Materials

The RO4003C material can be removed with a conventional nylon brush. No special handling is required before electroplating copper without electricity. The plate must be treated using a conventional epoxy/glass process. In general, it is not necessary to remove the borehole because the high TG resin system (280°C+[536°F]) does not discolor easily during the drilling process. If the stain is caused by an aggressive drilling operation, the resin can be removed using a standard CF4/O2 plasma cycle or by a dual alkaline permanganate process.

The RO4003C material surface may be mechanically and/or chemically prepared for light protection. It is recommended to use standard aqueous or semi-aqueous photoresists. Any commercially available copper wiper can be used. All filterable or photo solderable masks commonly used for epoxy/glass laminates adhere very well to the surface of ro4003C. Mechanical cleaning of exposed dielectric surfaces prior to application of welding masks and designated "registered" surfaces shall avoid optimum adhesion.

The cooking requirements of ro4000 materials are equivalent to those of epoxy/glass. Generally, equipment that does not cook epoxy/glass plates does not need to cook ro4003 plates. For installation of epoxy/baked glass as part of a conventional process, we recommend cooking at 300°F, 250°f (121°c-149°C) for 1 to 2 hours. Ro4003C does not contain flame retardant. It can be understood that a plate packaged in an infrared (IR) unit or operating at a very low transmission speed can reach temperatures in excess of 700°f (371°C); Ro4003C can start combustion at these high temperatures. Systems that still use infrared reflux devices or other equipment that can reach these high temperatures should take necessary precautions to ensure that there is no risk.

High-frequency laminates can be stored indefinitely at room temperature (55-85°F, 13-30°C), humidity. At room temperature, dielectric materials are inert at high humidity. However, metal coatings such as copper can oxidize when exposed to high humidity. Standard pre-cleaning of PCBS can easily remove corrosion from properly stored materials.

The RO4003C material can be machined using tools typically used for epoxy/glass and hard metal conditions. The copper foil must be removed from the guide channel to prevent smearing.

Rogers RO4350B/RO4003C Material Parameters

| Properties | RO4003C | RO4350B | Direction | Unit | Condition | Test Method |

| Dk(ε) | 3.38±0.05 | 3.48±0.05 | - | 10GHz/23℃ | IPC.TM.6502.5.5.5Clamp microstrip line test | |

| Dk(ε) | 3.55 | 3.66 | Z | - | 8 to 40GHz | Differential phase length method |

|

Loss factor(tan δ) |

0.00270.0021 | 0.00370.0031 | - | 10GHz/23℃2.5GHz/23℃ | IPC.TM.6502.5.5.5 | |

| Temperature coefficient ofdielectric constant | +40 | +50 | Z | ppm/℃ | 50℃ to 150℃ | IPC.TM.6502.5.5.5 |

| Volume Resistance | 1.7X100 | 1.2X1010 | MΩ.cm | COND A | IPC.TM.6502.5.17.1 | |

| Surface Resistance | 4.2X100 | 5.7X109 | MΩ | 0.51mm(0.0200) | IPC.TM.6502.5.17.1 | |

| Electrical Endurance | 31.2(780) | 31.2(780) | Z | KV/mm(V/mil) | RT | IPC.TM.6502.5.6.2 |

| Tensile Modulus | 19650(2850) 19450(2821) | 16767(2432) 14153(2053) | XY | MPa(kpsi) | RT | ASTM D638 |

| Tensile Strength | 139(20.2)100(14.5) | 203(29.5)130(18.9) | XY | MPa(kpsi) | ASTM D638 | |

| Bending Strength | 276(40) | 255(37) | MPa(kpsi) | IPC.TM.6502.4.4 | ||

| Dimensional Stability | <0.3 | <0.5 | X,Y | mm/m(mils/inch) | After the etching+E2/150℃ | IPC.TM.6502.4.39A |

| CTE | 111446 | 101232 | XYZ | ppm/℃ | 55 to 288℃ | IPC.TM.6502.4.41 |

| Tg | >280 | >280 | ℃ DSC | A | IPC.TM.6502.4.24 | |

| Td | 425 | 390 | ℃ TGA | ASTM D3850 | ||

| Thermal Conductivity | 0.71 | 0.69 | W/m/K | 80℃ | ASTM C518 | |

| Moisture Absorption Rate | 0.06 | 0.06 | % | 0.060" samples were immersed in water at 50°C for 48 hours | ASTM D570 | |

| Density | 1.79 | 1.86 | gm/cm3 | 23℃ | ASTM D792 | |

| Peel Strength | 1.05(6.0) | 0.88(5.0) | N/mm(pli) | 1 oz. EDC after tin bleaching | IPC.TM.6502.4.8 | |

| Flame Retardancy | N/A | V0 | UL94 | |||

| Lf Treatment Compatible | Yes | Yes |

Application Of RO4003C High Frequency PCB

Mobile communication products

Power Splitter, coupler, duplexer, filter and other passive devices

Power Amplifier, Low Noise Amplifier, etc

Automobile anti-collision system, satellite system, radio system and other fields

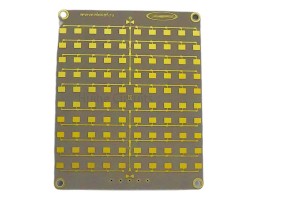

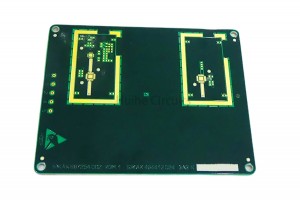

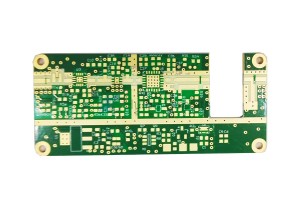

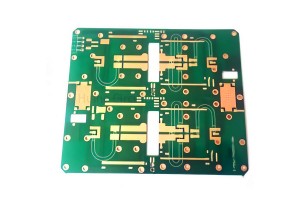

Equipment Display

PCB Automatic Plating Line

PCB PTH Line

PCB LDI