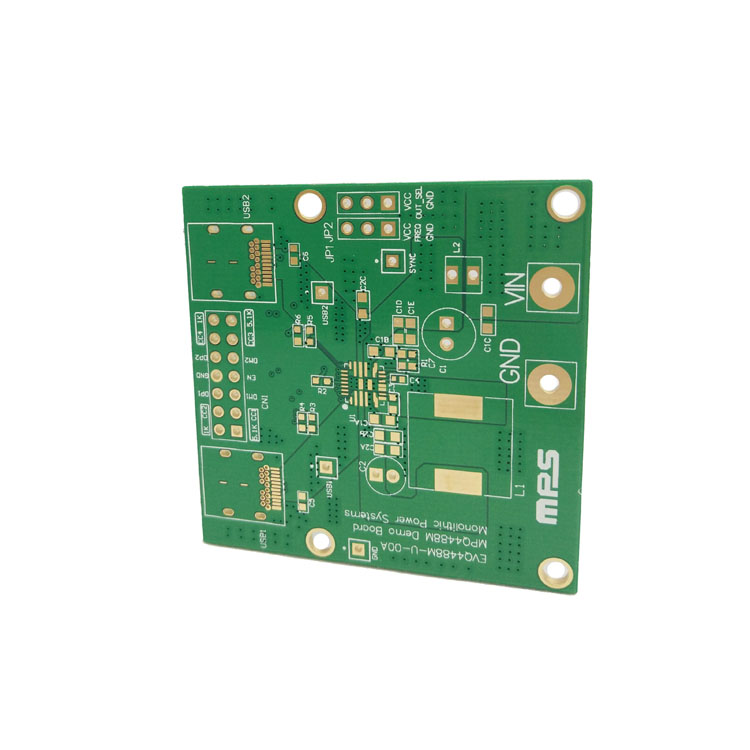

4 Layer ENIG FR4 Heavy Copper PCB

Heavy Copper PCB

Heavy copper PCB boards can be manufactured simply by a combination of two main processes, electroplating and etching. In contrast to other PCBS, the circuit is made of a thin layer of copper foil.

The heavy copper PCBs are uniformly laminated with FR4 or other epoxy-based material. The average weight of heavy copper PCBs can be 4 ounces (140μm), which is a better ratio than another common copper PCB.

The additional copper thickness allows the board to conduct higher currents, achieve good heat distribution, and enable complex switching in a limited space. Other advantages include increased mechanical strength at connector locations, the ability to create smaller product sizes by combining multiple weights in the same layer of the circuit, and the ability to use specialized materials with minimal risk of circuit failure.

Benefits Of Heavy Copper PCB

The manufacture of heavy copper PCBs involves the use of plating or etching, as it increases the thickness of the copper PCB in the side walls and plating holes. In addition, heavy copper PCBS are electroplated during PCB manufacturing. This helps to thicken the PTH wall on the PCB. Some characteristics of thick copper PCBS that differ from other PCBS include:

Copper Weight:

This is of course the main feature of a heavy copper PCB. It refers to the weight of copper used per square foot in ounces.

Cover

Outer copper foil. The copper weight of the outer layer is a standard design set in advance.

Inner Layer

The copper quality and dielectric thickness of the inner layer are predefined standard items. However, they can be adapted to the customized needs of the project.

Application Of Heavy Copper PCB

Heavy copper PCBs are used in a variety of applications, such as flat transformers, heat propagation, high power dispersion, control converters, etc. In PC, automotive, military and mechanical control, interest in overwhelmingly copper plated plates is growing. Heavy copper printed circuit boards are also widely used:

1. Power supply and control converter

2. Authority of appropriations

3. Welding tools or equipment

4. The auto industry

5. Solar panel manufacturers, etc